Wholesale Discount Bio Soluble Fiber - Bio Soluble Fiber Board / AES Board – MINYE

Wholesale Discount Bio Soluble Fiber - Bio Soluble Fiber Board / AES Board – MINYE Detail:

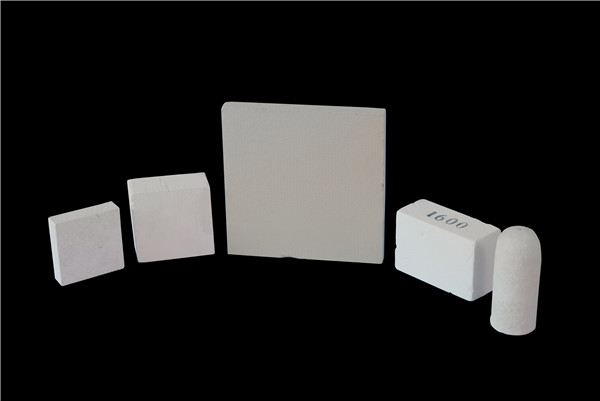

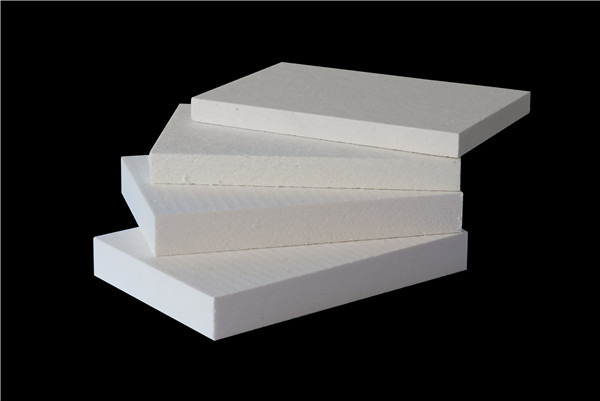

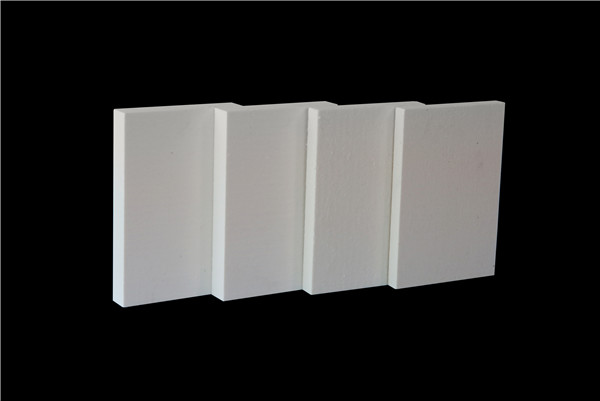

Product Description

Bio Soluble Fiber (Bio-Soluble Fiber) takes CaO, MgO, SiO2 as main chemical composition, is new type material produced with advanced technology. Bio Soluble Fiber is soluble in human body fluid, no harm to human health, is pollution free, harm free, green, environment-friendly refractory and insulation material.

Bio soluble fiber board raw material is bio soluble fiber bulk fiber, adding small quantity organic and inorganic binders, the production line is full automatic, continuous and highly advanced. Bio soluble fiber board has good flatness, precise size, good bending strength, easy cutting, even distribution and excellent insulation effect. Bio soluble fiber board is ideal insulation and refractory material for various industrial furnaces.

Typical Features

Low bio persistent

Low heat capacity, low thermal conductivity

Good bending strength, high rigidity, easy to process and install

Precise size, good flatness

Excellent thermal stability and thermal shock resistance

Typical Application

Metallurgical: Backup insulation, mold insulation.

Non-Ferrous: Tundish and electric tank back up lining.

Ceramics: Furnace hot face lining, fireproof plate

Glass: Bath back up lining

Petrochemical: Furnace hot face lining.

Typical product properties

| Bio Soluble Fiber Board Typical Product Properties | |

| Product Name | Bio Soluble Board |

| Temperature Grade℃ | 1260 |

| Recommended Operating Temperature℃ | ≤1100 |

| Permanent Linear Shrinkage(%) | 950℃×24h≤4 |

| Thermal Conductivity(Mean Temp 500℃)W/(m.k) | ≤0.153 |

| Water Content(%) | ≤1 |

| Loss on ignition(%) | ≤8 |

| Nominal Density(kg/m³) | 220~400 |

| SiO2 (%) | 60-68 |

| CaO (%) | 25-35 |

| MgO (%) | 4-7 |

| Al2 O3 | <1.0 |

| Availability Standard | 600/1200mm Width; 900mm/1000mm Length; Thickness 3mm~100mm |

Note: Test data shown are average results of tests conducted under standard procedures and are subject to variation. Results should not be used for specification purposes. The products listed comply to ASTM C892.

Product detail pictures:

Related Product Guide:

Our company aims to operating faithfully, serving to all of our customers , and working in new technology and new machine constantly for Wholesale Discount Bio Soluble Fiber - Bio Soluble Fiber Board / AES Board – MINYE , The product will supply to all over the world, such as: Bahamas, Birmingham, Mecca, By continuous innovation, we will provide you with more valuable products and services, and also make a contribution for the development of the automobile industry at home and abroad. Both domestic and foreign merchants are strongly welcomed to join us to grow together.

This is a very professional wholesaler, we always come to their company for procurement, good quality and cheap.