Original Factory Ceramic Fiber Material - Ceramic Fiber Foam Product / RCF Foam – MINYE

Original Factory Ceramic Fiber Material - Ceramic Fiber Foam Product / RCF Foam – MINYE Detail:

Product Description

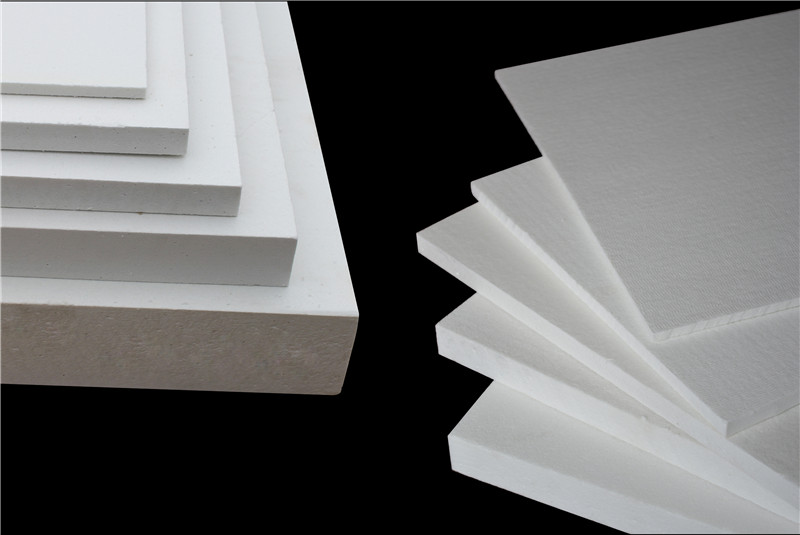

Ceramic fiber foam technology is firstly using special technology to combine ceramic fiber bulk fiber with water-based binder, then use special device to spray foam on equipment surface. After drying foam become stable ,seamless, strong and thick enough. Ceramic fiber foam is non-toxic, tasteless, acid and alkali resistant, antibacterial, durable etc.

Typical Features

Low thermal conductivity, good insulation

Excellent fireproof

Excellent sound absorption

Excellent chemical stability, durable

Typical Application

Steel structure fireproof

Petrochemical heating furnace

Metallurgical heating furnace

Hot pipe lining

Typical product properties

| Foam Product Typical Product Properties | |||

| Product Code | Standard Purity Foam | High Alumina Foam | Standard Zirconium Foam |

| Temperature Grade℃ | 1260 | 1350 | 1430 |

| Nominal Density(kg/m³) | 220 ± 15 | 220 ± 15 | 220 ± 15 |

| Thermal Conductivity(Mean Temp 500℃)W/(m.k) | ≤ 0.153 | ≤ 0.153 | ≤ 0.153 |

| Permanent Linear Shrinkage(%) | 1260℃×6h≤3 | 1350℃×6h≤3 | 1430℃×6h≤3 |

| ISO Quality Certification | ISO9001-2008, ISO14001-2004 | ||

| Note: Test data shown are average results of tests conducted under standard procedures and are subject to variation. Results should not be used for specification purposes. The products listed comply to ASTM C892. | |||

Product detail pictures:

Related Product Guide:

We insist over the principle of enhancement of 'High high quality, Efficiency, Sincerity and Down-to-earth working approach' to offer you with superb assistance of processing for Original Factory Ceramic Fiber Material - Ceramic Fiber Foam Product / RCF Foam – MINYE , The product will supply to all over the world, such as: Vietnam, Nigeria, Uruguay, We have the best products and professional sales and technical team.With the development of our company, we are able to provide customers best products, good technical support, perfect after-sales service.

As an international trading company, we have numerous partners, but about your company, I just want to say, you are really good, wide range, good quality, reasonable prices, warm and thoughtful service, advanced technology and equipment and workers have professional training, feedback and product update is timely, in short, this is a very pleasant cooperation, and we look forward to the next cooperation!

Write your message here and send it to us