OEM/ODM Manufacturer Refractory Castable - Light-weight insulation/refractory castable – MINYE

OEM/ODM Manufacturer Refractory Castable - Light-weight insulation/refractory castable – MINYE Detail:

Product Description

Light-weight refractory insulation castable is produced with high-quality light-weight aggregate, powder, admixture and binder. Density ranges from 0.6 to 1.7g/cm3 and the service temperature ranges from 800℃ to 1650 ℃.

Typical Features

low density, low thermal conductivity, excellent insulation

Lightweight refractory castable can direct contact flame.

Good integration, long service life, easy installation, moldable

Typical Application

metallurgy industrial furnace, heat treatment furnace

chemical industrial furnace

waste incinerator ,circulating fluidized bed boiler

Typical product properties

|

Light-weight insulation castable Product Properties |

|||||||

| Product Code | MYLC-165 | MYLC-160 | MYLC-145 | MYLC-140 | MYLC-135 | MYLC-130 | |

| Classification Temperature (℃) | 1650 | 1600 | 1450 | 1400 | 1350 | 1300 | |

| Density (g/cm³) | 1.5 | 1.5 | 1.7 | 1.7 | 1.4 | 1.4 | |

| compressive strength(Mpa) | 110℃ x 24 h | 7.5 | 17 | 25 | 25 | 6 | 5.5 |

| 1300℃ x 3 h | 20 | 22 | 20 | 20 | 5 | 5 | |

| Permanent linear thrinkage (℃×3h) (%) | 0.4 (1650) | 0.5 (1600) | 0.6 (1450) | 0.8 (1400) | 0.7 (1350) | 0.7 (1300) | |

| Thermal conductivity (W/m.k) | 400℃ | 0.42 | 0.42 | 0.58 | 0.58 | 0.4 | 0.38 |

| Note: Test data shown are average results of tests conducted under standard procedures and are subject to variation. Results should not be used for specification purposes. The products listed comply to ASTM C892. | |||||||

|

Light-weight refractory castable Product Properties |

||||||

| Product Code | MYLC-130 | MYLC-125 | MYLC-120 | MYLC-110 | MYLC-100 | |

| Classification Temperature (℃) | 1300 | 1250 | 1200 | 1100 | 1000 | |

| Density (g/cm³) | 1.4 | 1.3 | 1.2 | 1.1 | 1 | |

| compressive strength(Mpa) | 1000℃ x 3 h | 5 | 6 | 4 | 4 | 4 |

| Thermal conductivity (W/m.k) | 600℃ | 0.36 | 0.33 | 0.32 | 0.3 | 0.28 |

| Permanent linear thrinkage (℃×3h) (%) | 0.6 (1300) | 0.7 (1250) | 0.6 (1200) | 0.6 (1100) | 0.5 (1000) | |

| Chemical composition (%) | Al2O3 | 43 | 42 | 32 | 32 | 30 |

| Note: Test data shown are average results of tests conducted under standard procedures and are subject to variation. Results should not be used for specification purposes. The products listed comply to ASTM C892. | ||||||

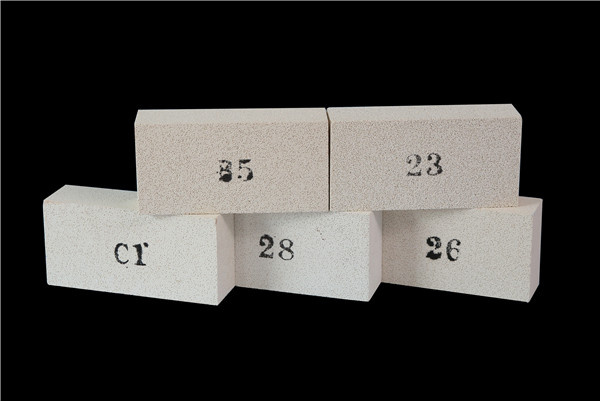

Product detail pictures:

Related Product Guide:

We normally think and practice corresponding towards the change of circumstance, and grow up. We aim at the achievement of a richer mind and body plus the living for OEM/ODM Manufacturer Refractory Castable - Light-weight insulation/refractory castable – MINYE , The product will supply to all over the world, such as: Barcelona, Croatia, Australia, We follow up the career and aspiration of our elder generation, and we are eager to open up a new prospect in this field, We insist on "Integrity, Profession, Win-win Cooperation", because we have a strong backup, that are excellent partners with advanced manufacturing lines, abundant technical strength, standard inspection system and good production capacity.

It is not easy to find such a professional and responsible provider in today's time. Hope that we can maintain long-term cooperation.

Write your message here and send it to us