Manufactur standard Ceramic Fiber Block - Ceramic Fiber Vacuum Forming Shapes – MINYE

Manufactur standard Ceramic Fiber Block - Ceramic Fiber Vacuum Forming Shapes – MINYE Detail:

Product Description

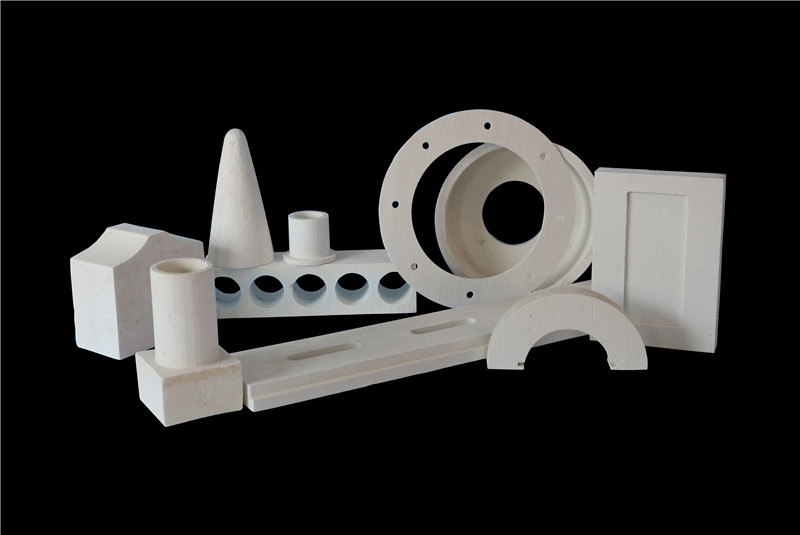

Ceramic fiber vacuum forming shape is manufactured in vacuum forming processing with ceramic fiber bulk fiber. It is special shape product designed to satisfy special demand in some industrial specific sector. Each vacuum forming product need same size and shape mould. Per different quality requirement, different binders and additives are used. Vacuum forming shape has low thermal conductivity, good insulation effect, light weight and high shock resistance etc features.

Typical Features

Low heat capacity, low thermal conductivity

Excellent chemical stability

Excellent thermal stability and thermal shock resistance

Excellent anti-wind erosion

Typical Application

Industrial furnace door, burner brick, peep hole, thermometer hole

Aluminium collecting tank and launder

Special metallurgy tundish, crucible furnace, casting mouth furnace, insulation casting head, RCF crucible

Thermal radiation Insulation in civil and industrial heater

Various special burning chamber, lab electrical furnace

Typical product properties

| Ceramic Fiber Vacuum Forming Shapes Typical Product Properties | ||||

| VF Shape Product | Standard Purity | HP Shapes | High Al Purity Shape | AZS Shape |

| Product Code | MYTX-BZ-05 | MYTX-GC-05 | MYTX-GL-05 | MYTX-HG-05 |

| Permanent Linear Shrinkage(%) | 1000℃×24h≤4 | 1100℃×24h≤4 | 1200℃×24h≤4 | 1350℃×24h≤4 |

| Availability | Per customers’ drawing | |||

| Note: Test data shown are average results of tests conducted under standard procedures and are subject to variation. Results should not be used for specification purposes. The products listed comply to ASTM C892. | ||||

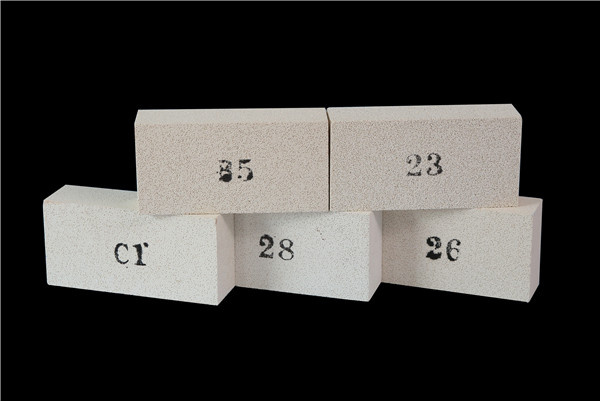

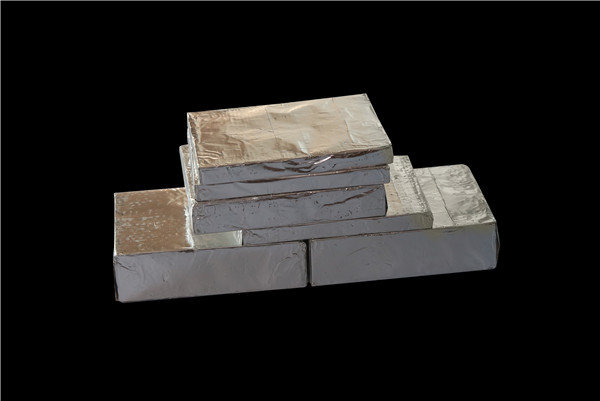

Product detail pictures:

Related Product Guide:

Usually customer-oriented, and it's our ultimate focus on to be not only by far the most reliable, trustable and honest provider, but also the partner for our customers for Manufactur standard Ceramic Fiber Block - Ceramic Fiber Vacuum Forming Shapes – MINYE , The product will supply to all over the world, such as: Jordan, New Orleans, Danish, Each product is carefully made, it will make you satisfied. Our products in the production process have got strictly monitored, because it is only to provide you the best quality, we will feel confident. High production costs but low prices for our long-term cooperation. You can have a variety choices and the value of all types are same reliable. If you have any question, do not hesitate to ask us.

This is a reputable company, they have a high level of business management, good quality product and service, every cooperation is assured and delighted!