Hot-selling Refractory Insulation Blanket - Microporous Insulation Board – MINYE

Hot-selling Refractory Insulation Blanket - Microporous Insulation Board – MINYE Detail:

Product Description

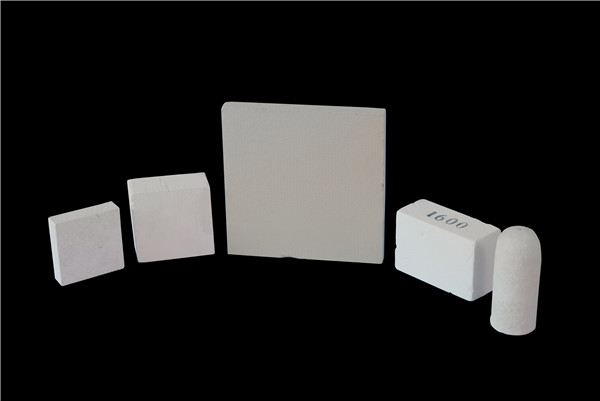

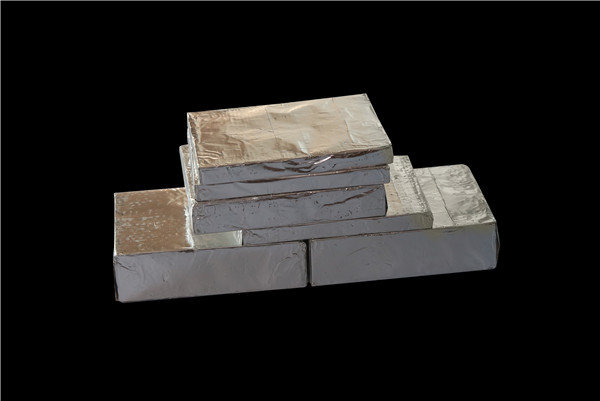

Microporous board is made with special technology using various raw materials, the thermal conductivity is lower than stationary air under atmospheric pressure, only 1/4 to 1/10 than ceramic fiber insulation material, it is the best lowest thermal conductivity solid material. In some high temp equipment which requiring space and weight, microporous board is the best, sometimes the only option. The birth of this materials has promoted related high temp equipment designing innovation.

Typical Features

Super low thermal conductivity and thermal loss

Low heat storage

Excellent thermal stability

Environment friendly

Easy cutting and processing

Long service life

Typical Application

Iron & Steel ( Tundish, ladel, torpedo ladel)

Petrochemical (Pyrolyzer, Hydrogen Transform Furnace, reformer furnace, heating furnace)

Glass (Float glass furnace, glass tempering furnace, bending furnace)

Heat treatment: electric furnace, car-heater, Annealing furnace, tempering furnace etc.

Pipe insulation

Ceramic industry

Power Generation

Domestic appliance

Aerospace

Shipping

mine rescue capsule

Typical product properties

| Microporous Board Typical Product Properties | ||

| Product Name | Microporous Board | |

| Product Code | MYNMB-1000 | |

| Microporous Rate | 90% | |

| Permanent Linear Shrinkage(800℃,12h) | <3% | |

| Nominal Density(kg/m3) | 280kg/m3±10% | |

| Thermal Conductivity(W/m·k) | 200℃ | <0.022 |

| 400℃ | <0.025 | |

| 600℃ | <0.028 | |

| 800℃ | <0.034 | |

| Availability: Thickness: 5mm~50mm | ||

| Note: Test data shown are average results of tests conducted under standard procedures and are subject to variation. Results should not be used for specification purposes. The products listed comply to ASTM C892. | ||

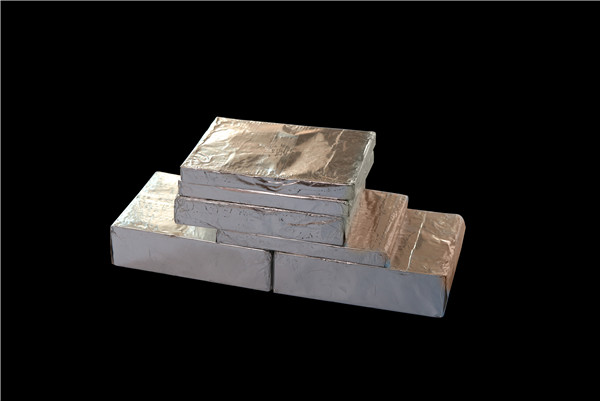

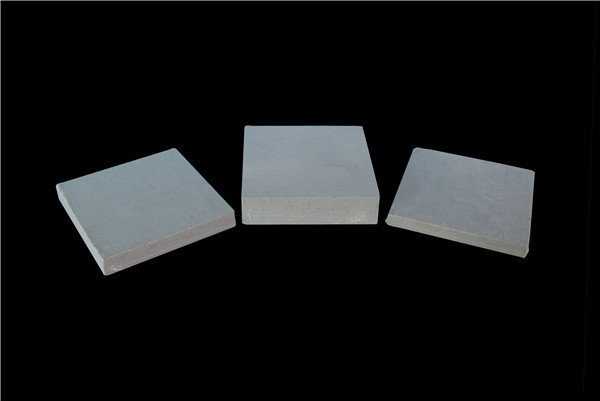

Product detail pictures:

Related Product Guide:

Bear "Customer initially, High-quality first" in mind, we work closely with our prospects and supply them with efficient and specialist companies for Hot-selling Refractory Insulation Blanket - Microporous Insulation Board – MINYE , The product will supply to all over the world, such as: Congo, Norway, Seychelles, To meet the requirements of individual customers for each bit more perfect service and stable quality products. We warmly welcome customers around the world to visit us, with our multi-faceted cooperation, and jointly develop new markets, create a brilliant future!

The product manager is a very hot and professional person, we have a pleasant conversation, and finally we reached a consensus agreement.