Hot Selling for Ceramic Fiber Brick - Ceramic Fiber Felt / RCF Felt – MINYE

Hot Selling for Ceramic Fiber Brick - Ceramic Fiber Felt / RCF Felt – MINYE Detail:

Product Description

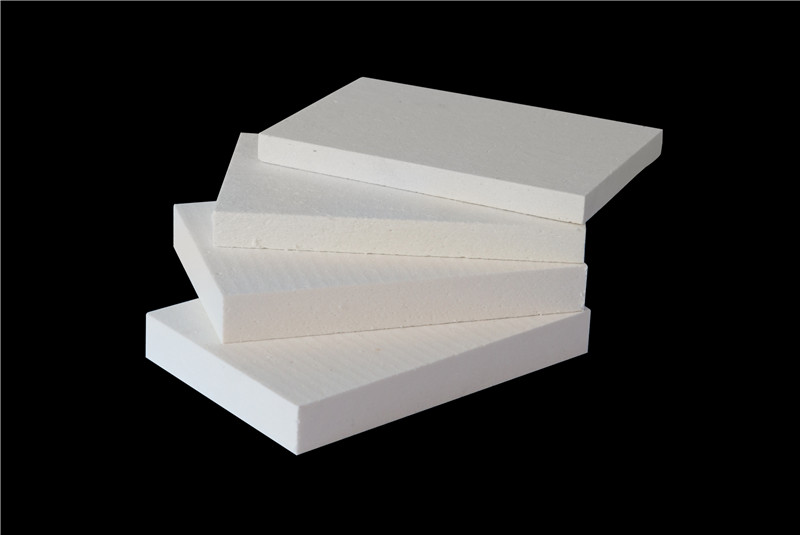

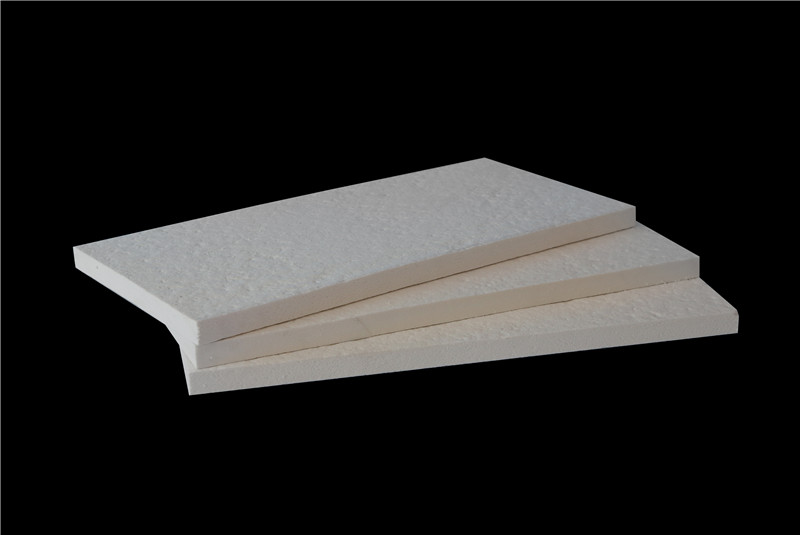

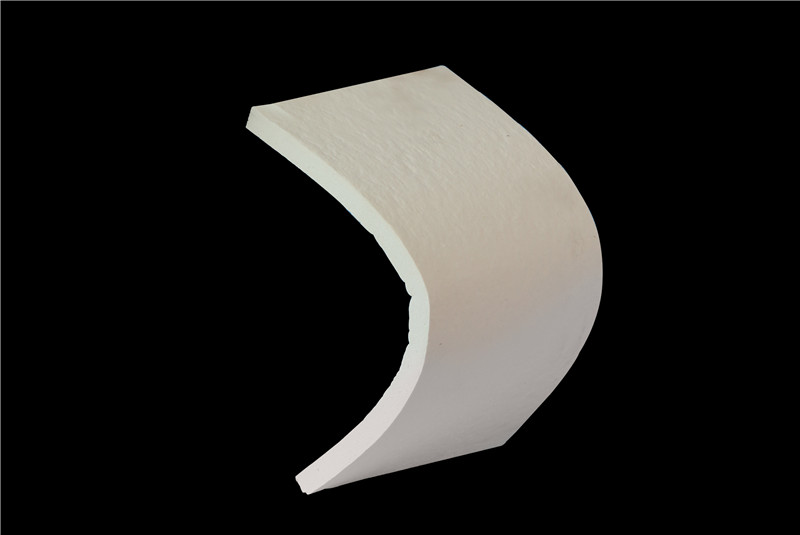

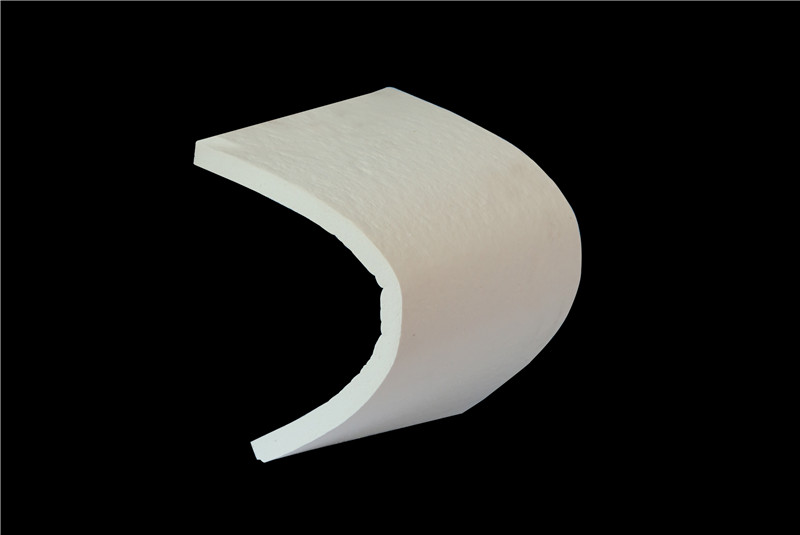

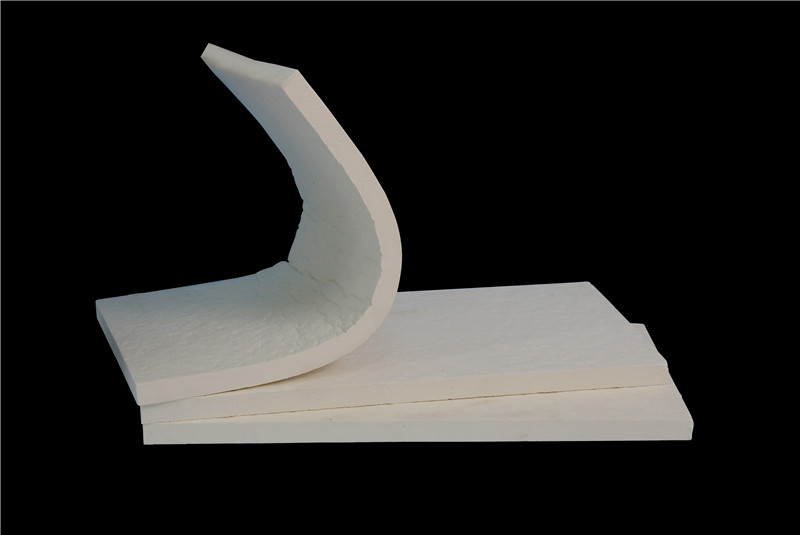

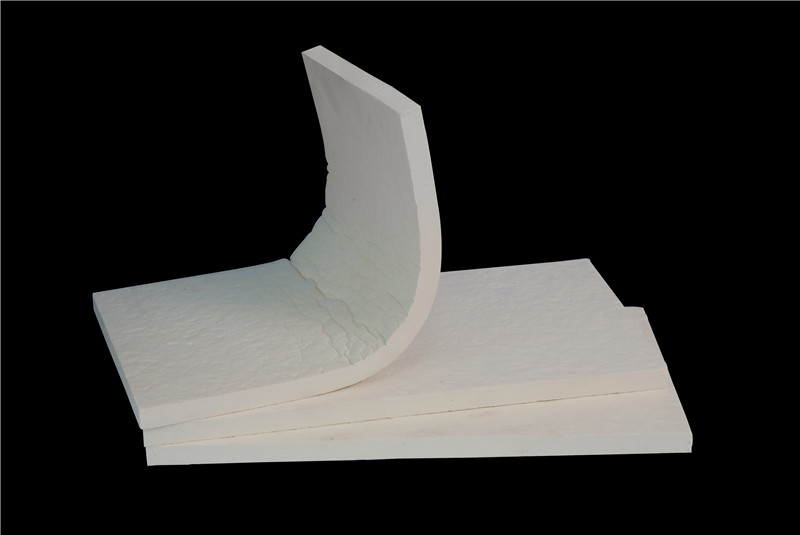

Ceramic fiber felt take ceramic fiber bulk as raw material, processed in vacuum forming technology, is light, high ductility insulating material. Ceramic fiber felt has good strength and elasticity, is multiple function product used in various furnace, boiler lining, high temp gasket and back up lining.

Typical Features

Low Heat Capacity, Low Thermal Conductivity

Excellent Chemical stability

Excellent Thermal Stability

Excellent Sound Absorption

Soft and Elastic, easy to cut and process

Typical Application

Furnace lining

Insulation for high temp equipment

High temp gasket, expansion sealing

Insulation for metal distribution

Typical product properties

| Ceramic Fiber Felt Typical Product Properties | ||||||

| Felt Product | Normal Kaolin | Standard Purity | High Purity | High Al Purity | Lower AZS | Standard AZS |

| Temperature Grade℃ | 1050 | 1260 | 1260 | 1300 | 1300 | 1430 |

| Recommended Operating Temperature℃ | ≤950 | ≤1100 | ≤1150 | ≤1200 | ≤1200 | ≤1250 |

| Product Code | MYTX-PT-03 | MYTX-BZ-03 | MYTX-GC-03 | MYTX-GL-03 | MYTX-DG-03 | MYTX-HG-03 |

| Permanent Linear Shrinkage(%) | 950℃×24h≤4 | 1000℃×24h≤4 | 1100℃×24h≤4 | 1200℃×24h≤4 | 1250℃×24h≤4 | 1350℃×24h≤4 |

| Thermal Conductivity(Mean Temp 500℃)W/(m.k) | ≤0.153 | |||||

| Water Content(%) | ≤1 | |||||

| Loss On Ignition(%) | ≤8 | |||||

| Nominal Density(kg/m³) | 180~220 | |||||

| Al2 O3 | 34~36 | 36~38 | 39~42 | 45~47 | 38~40 | |

| Al2 O3 +SiO2 | ≥95 | ≥96 | ≥98 | ≥99 | ≥90 | |

| Al2 O3 +SiO2 +ZrO2 | ≥99 | |||||

| ZrO2 | 5~7 | ≥15 | ||||

| Fe2 O3 | <1.0 | <0.5 | ||||

| Availability (Standard Product) | 600x400x20~50 900x600x10~50 1000x600x10~50 | |||||

| Note: Test data shown are average results of tests conducted under standard procedures and are subject to variation. Results should not be used for specification purposes. The products listed comply to ASTM C892. | ||||||

Product detail pictures:

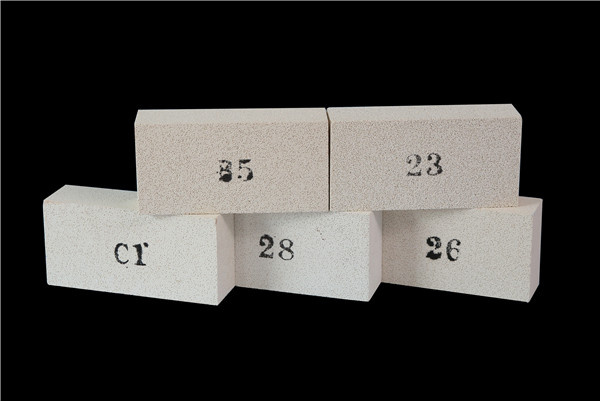

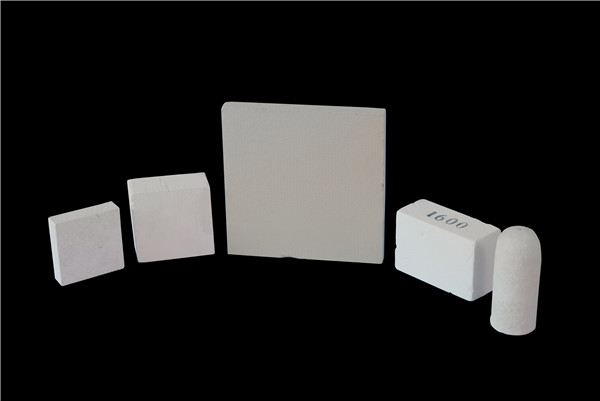

Related Product Guide:

We've been convinced that with joint efforts, the enterprise between us will bring us mutual benefits. We could guarantee you item excellent and aggressive price tag for Hot Selling for Ceramic Fiber Brick - Ceramic Fiber Felt / RCF Felt – MINYE , The product will supply to all over the world, such as: Denmark, Nepal, Gambia, We hope we can establish long-term cooperation with all of the customers. And hope we can improve competitiveness and achieve the win-win situation together with the customers. We sincerely welcome the customers from all over the world to contact us for anything you need!

We feel easy to cooperate with this company, the supplier is very responsible, thanks.There will be more in-depth cooperation.

Write your message here and send it to us