High Performance Monolithic Refractory Cement - Monolithic Module – MINYE

High Performance Monolithic Refractory Cement - Monolithic Module – MINYE Detail:

Product Description

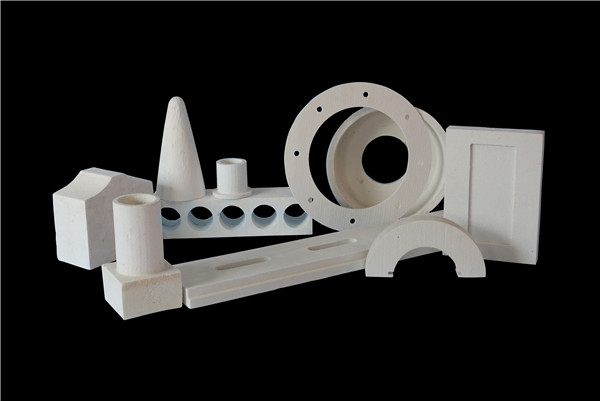

Ceramic fiber monolithic module is a unique creative solution for furnace insulation lining, it is a whole monolithic module without compressing. Monolithic module is made with high purity alumina, silicon and zirconium sand etc, whole full-automatic process include electric furnace melting, spunning, fiber collecting, needling and CNC cutting etc. Minye monolithic module is avaliable in 1260℃ and 1430 ℃ Temp, it is ideal fast installation furnace lining in various industries.

Typical Features

Multiple directions compression-It can be compressed in four directions, which can achieve max expansion in installation directions to get no leaking and good thermal insulation.

Completed seamless structure-After calcination, the product is transformed into a high-strength, seamless and solid structure from a soft and compressible monolithic block, which is high integrity and firmed.

Low shrinkage in high temperature-The cold surface of the product touch furnace wall closely to achieve maximum extrusion between modules, ensuring low shrinkage in high temperature and achieving structural integrity.

Customized- It is suitable for both planar structures and cutting installation in special shape parts. Various shapes are customized per demand.

Typical Application

Petrochemical: Ethylene cracking furnace, Reforming furnace, Hydrogenation furnace, homogenizing furnace, and process heater etc.

Iron & Steel: Continuous heat treat furnace, blast furnace, forging furnace, hot gas pipe and flue pipes etc.

Power Generation: HRGS, RTO, hot gas pipe and flue pile etc

Ceramics: Tunnel kiln, roller kiln, shuttle kiln, kiln cars.

Typical product properties

| Monolithic Module Typical Product Properties | ||

| Product Code | MYTX-GC-10 | MYTX-HG-10 |

| Temperature Grade℃ | 1260 | 1430 |

| Nominal Density(kg/m³) | 192~240 | 192~240 |

| Permanent Linear Shrinkage(%) | 1100℃×24h≤3 | 1350℃×24h≤3 |

| Resilience (%) | ≥80 | ≥80 |

| Anchor material | 304S | 310S |

| Anchor type | Side Anchor/Wing Anchor | Side Anchor/Wing Anchor |

| Package dimension | 300 x 300 x insulation thickness | 300 x 300 x insulation thickness |

| Package | Carton with moisture plastic bag | Carton with moisture plastic bag |

| Note: Test data shown are average results of tests conducted under standard procedures and are subject to variation. Results should not be used for specification purposes. The products listed comply to ASTM C892. | ||

Product detail pictures:

Related Product Guide:

Fast and very good quotations, informed advisers to help you choose the correct merchandise that suits all your preferences, a short creation time, responsible excellent command and different companies for paying and shipping affairs for High Performance Monolithic Refractory Cement - Monolithic Module – MINYE , The product will supply to all over the world, such as: London, Kenya, Monaco, Our advanced equipment, excellent quality management, research and development ability make our price down. The price we offering may not be the lowest, but we guarantee it is absolutely competitive! Welcome to contact us immediately for future business relationship and mutual success!

The accounts manager made a detailed introduction about the product, so that we have a comprehensive understanding of the product, and ultimately we decided to cooperate.