Good quality Alumina Fiber Board - Polycrystalline Fiber/Alumina Fiber Bulk/Blanket – MINYE

Good quality Alumina Fiber Board - Polycrystalline Fiber/Alumina Fiber Bulk/Blanket – MINYE Detail:

Product Description

Polycrystalline fiber bulk has low density, low thermal conductivity, good thermal shock resistance, high working temp, good chemical stability, good anti-corrosion etc features, it is widely used in metallurgy, construction, ceramics, aerospace, military etc industries.

PCW blanket is made by PCW fiber, double side needled, contains no binder or other additives. Under oxidation atmosphere, neutral atmosphere, and weak reducing atmosphere, PCW blanket still keeps good strength, softness and fiber structure.

PCW blanket has better acid-alkaline erosion resistance than alumina silicate fiber. PCW blanket thermal insulation effect is very excellent because it contain no any shot.

Typical Features of PCW blanket

Low thermal conductivity

Low shrinkage under high temp

Excellent thermal shock resistance

Ideal module feeding material, good softness under high temp

Low heat capacity

Good sound absorption

High strength, easy processing, no tears and holes around anchor area.

Good chemical stability and erosion resistance.

Typical Application

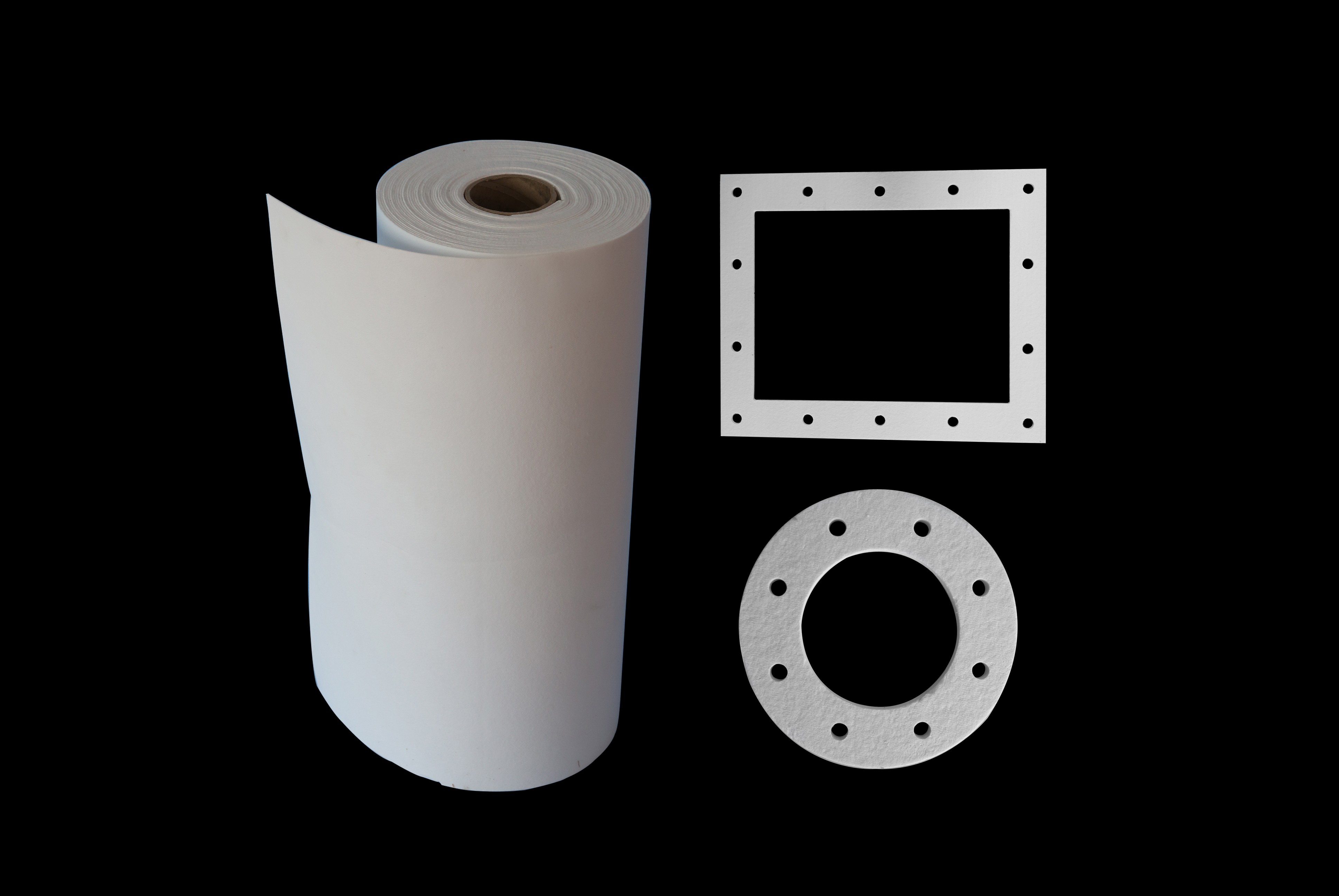

PCW fiber: PCW blanket, felt, board, VF shapes etc feeding, furnace lining above 1400℃; sealing in high temp furnace expansion joints; piston, brake pad etc strengthening materials; insulation material in rocket motor or other aerospace, military insulation material; Vehicle Catalytic Converter gasket material in European Ⅲ and above exhaust emission standards.

PCW blanket: Hihg Temp furnace lining, ceramics fast firing furnace, petrochemical furnace, high temp sealing gasket, furnace door sealing, high temp filter media.

Typical Features of PCW Bulk

Low thermal conductivity, low heat capacity

Excellent chemical stability

Excellent thermal stability

Containing no binder and erosion materials

Good softness and tensile strength under high temp

Typical product properties

| Polycrystalline Fiber Bulk/blanket Typical Product Properties | |||

| PCW Product | Veneer Module | Veneer Module | PCW Blanket |

| Product Code | MYPCW-72 | MYPCW-80 | MYPCW-72T |

| Temperature Grade(°C) | 1600 | 1600 | 1600 |

| Nominal Density(kg/m³) | 100 | 100 | 100~130 |

| Permanent Linear Shrinkage(%) | (1400°Cx6hr)<1.5 | (1500°Cx6hr)<1 | (1500°Cx6hr)<1 |

| Al2 O3(%) | 72 | 80 | 72 |

| Al2 O3 +SiO2(%) | ≥98.8 | ≥99 | ≥99.7 |

| Fe2 O3(%) | 0.1 | ||

| Availability | 200x100x50 | 200x100x50 | 7200x610x6/12.5/25 |

| Note: Test data shown are average results of tests conducted under standard procedures and are subject to variation. Results should not be used for specification purposes. The products listed comply to ASTM C892. | |||

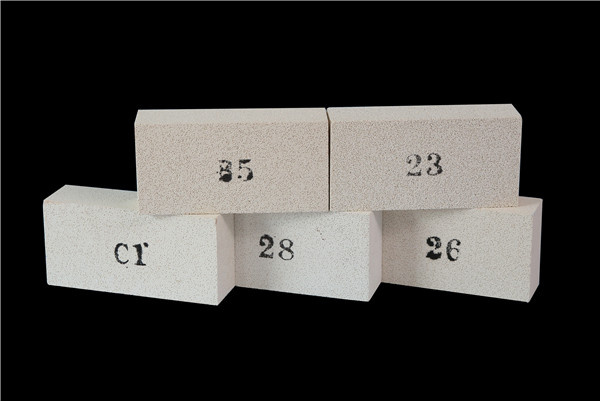

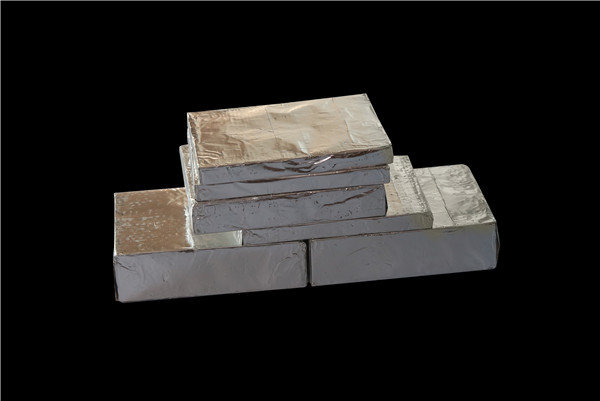

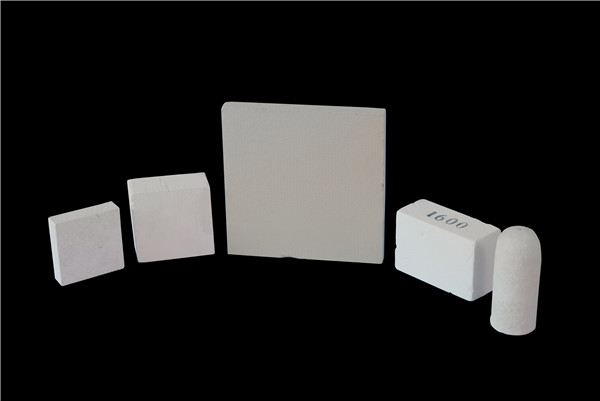

Product detail pictures:

Related Product Guide:

Our enhancement depends around the sophisticated devices ,exceptional talents and repeatedly strengthened technology forces for Good quality Alumina Fiber Board - Polycrystalline Fiber/Alumina Fiber Bulk/Blanket – MINYE , The product will supply to all over the world, such as: Stuttgart, Kyrgyzstan, Madrid, Our tenet is "integrity first, quality best". We have confidence in providing you with excellent service and ideal products. We sincerely hope we can establish win-win business cooperation with you in the future!

High Quality, High Efficiency, Creative and Integrity, worth having long-term cooperation! Looking forward to the future cooperation!