Free sample for High Temp Ceramic Insulation - Microporous Insulation Board – MINYE

Free sample for High Temp Ceramic Insulation - Microporous Insulation Board – MINYE Detail:

Product Description

Microporous board is made with special technology using various raw materials, the thermal conductivity is lower than stationary air under atmospheric pressure, only 1/4 to 1/10 than ceramic fiber insulation material, it is the best lowest thermal conductivity solid material. In some high temp equipment which requiring space and weight, microporous board is the best, sometimes the only option. The birth of this materials has promoted related high temp equipment designing innovation.

Typical Features

Super low thermal conductivity and thermal loss

Low heat storage

Excellent thermal stability

Environment friendly

Easy cutting and processing

Long service life

Typical Application

Iron & Steel ( Tundish, ladel, torpedo ladel)

Petrochemical (Pyrolyzer, Hydrogen Transform Furnace, reformer furnace, heating furnace)

Glass (Float glass furnace, glass tempering furnace, bending furnace)

Heat treatment: electric furnace, car-heater, Annealing furnace, tempering furnace etc.

Pipe insulation

Ceramic industry

Power Generation

Domestic appliance

Aerospace

Shipping

mine rescue capsule

Typical product properties

| Microporous Board Typical Product Properties | ||

| Product Name | Microporous Board | |

| Product Code | MYNMB-1000 | |

| Microporous Rate | 90% | |

| Permanent Linear Shrinkage(800℃,12h) | <3% | |

| Nominal Density(kg/m3) | 280kg/m3±10% | |

| Thermal Conductivity(W/m·k) | 200℃ | <0.022 |

| 400℃ | <0.025 | |

| 600℃ | <0.028 | |

| 800℃ | <0.034 | |

| Availability: Thickness: 5mm~50mm | ||

| Note: Test data shown are average results of tests conducted under standard procedures and are subject to variation. Results should not be used for specification purposes. The products listed comply to ASTM C892. | ||

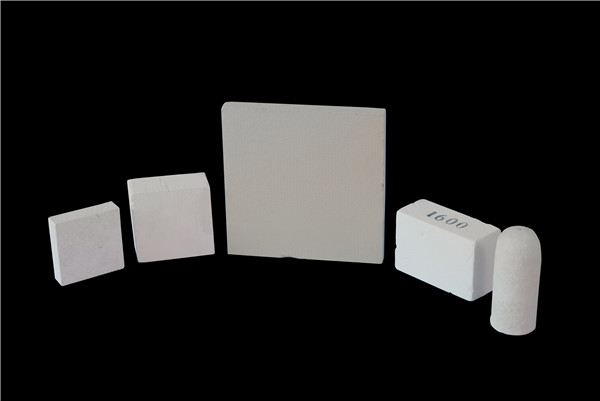

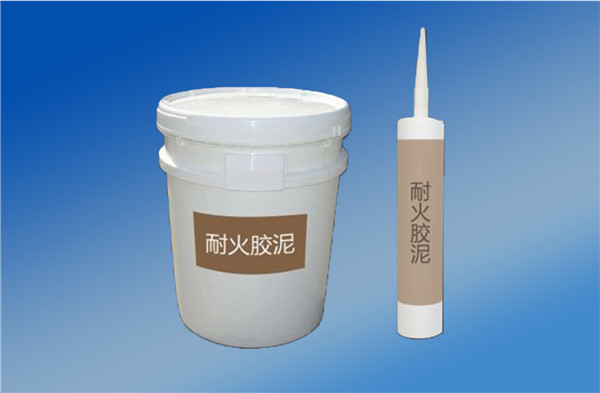

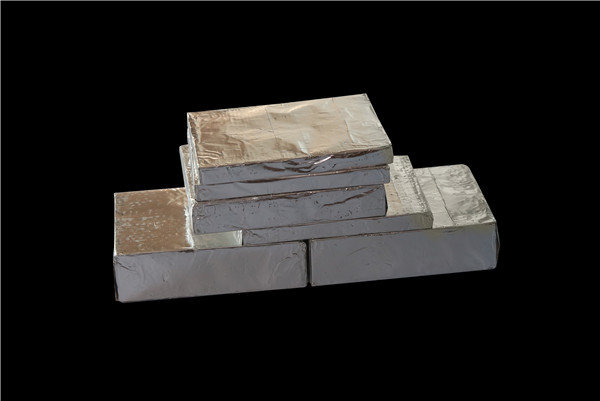

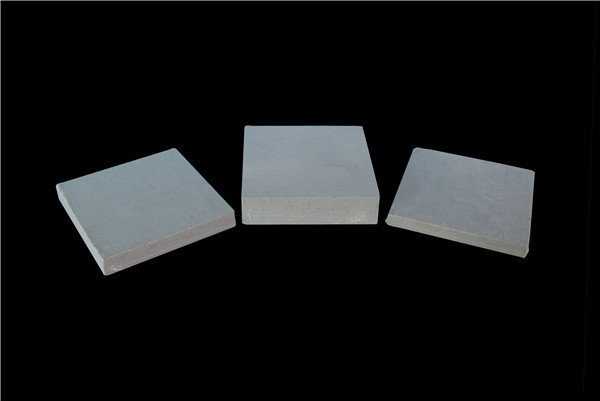

Product detail pictures:

Related Product Guide:

During the past few years, our business absorbed and digested state-of-the-art technologies the two at home and abroad. Meanwhile, our firm staffs a group of experts devoted to your development of Free sample for High Temp Ceramic Insulation - Microporous Insulation Board – MINYE , The product will supply to all over the world, such as: Ecuador, Uruguay, Ireland, Our solutions have national accreditation standards for experienced, premium quality goods, affordable value, was welcomed by people around the globe. Our products will continue to increase in the order and look forward to cooperation with you, Truly must any of people goods be of interest to you, make sure you letus know. We're likely to be delighted to give you a quotation up on receipt of one's in depth specs.

As an international trading company, we have numerous partners, but about your company, I just want to say, you are really good, wide range, good quality, reasonable prices, warm and thoughtful service, advanced technology and equipment and workers have professional training, feedback and product update is timely, in short, this is a very pleasant cooperation, and we look forward to the next cooperation!