Fast delivery High Temperature Ceramic Insulation - Microporous Insulation Board – MINYE

Fast delivery High Temperature Ceramic Insulation - Microporous Insulation Board – MINYE Detail:

Product Description

Microporous board is made with special technology using various raw materials, the thermal conductivity is lower than stationary air under atmospheric pressure, only 1/4 to 1/10 than ceramic fiber insulation material, it is the best lowest thermal conductivity solid material. In some high temp equipment which requiring space and weight, microporous board is the best, sometimes the only option. The birth of this materials has promoted related high temp equipment designing innovation.

Typical Features

Super low thermal conductivity and thermal loss

Low heat storage

Excellent thermal stability

Environment friendly

Easy cutting and processing

Long service life

Typical Application

Iron & Steel ( Tundish, ladel, torpedo ladel)

Petrochemical (Pyrolyzer, Hydrogen Transform Furnace, reformer furnace, heating furnace)

Glass (Float glass furnace, glass tempering furnace, bending furnace)

Heat treatment: electric furnace, car-heater, Annealing furnace, tempering furnace etc.

Pipe insulation

Ceramic industry

Power Generation

Domestic appliance

Aerospace

Shipping

mine rescue capsule

Typical product properties

| Microporous Board Typical Product Properties | ||

| Product Name | Microporous Board | |

| Product Code | MYNMB-1000 | |

| Microporous Rate | 90% | |

| Permanent Linear Shrinkage(800℃,12h) | <3% | |

| Nominal Density(kg/m3) | 280kg/m3±10% | |

| Thermal Conductivity(W/m·k) | 200℃ | <0.022 |

| 400℃ | <0.025 | |

| 600℃ | <0.028 | |

| 800℃ | <0.034 | |

| Availability: Thickness: 5mm~50mm | ||

| Note: Test data shown are average results of tests conducted under standard procedures and are subject to variation. Results should not be used for specification purposes. The products listed comply to ASTM C892. | ||

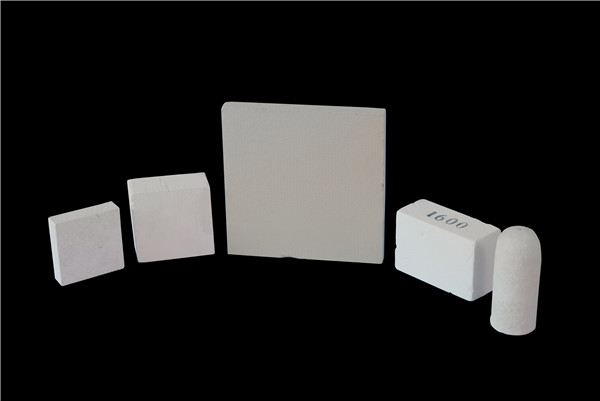

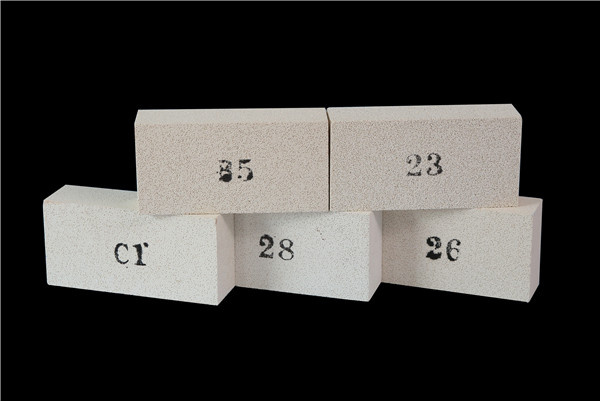

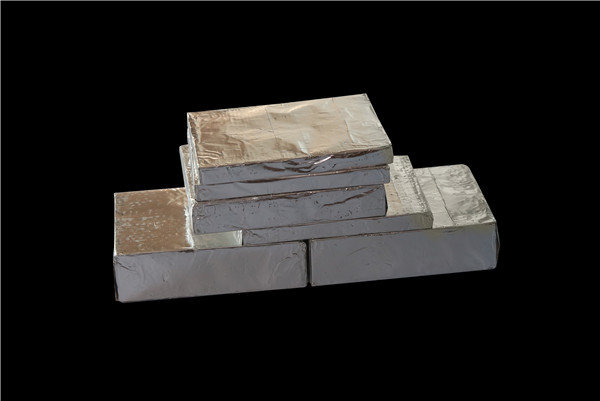

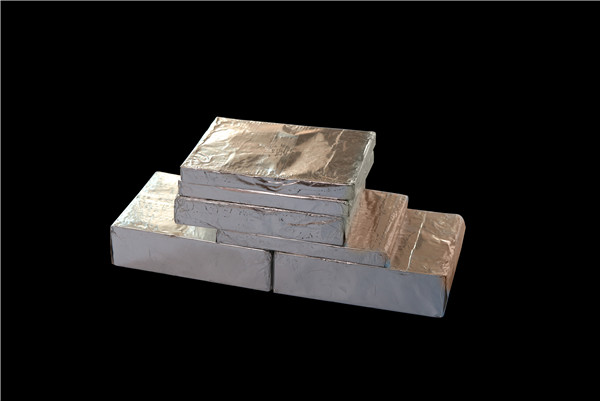

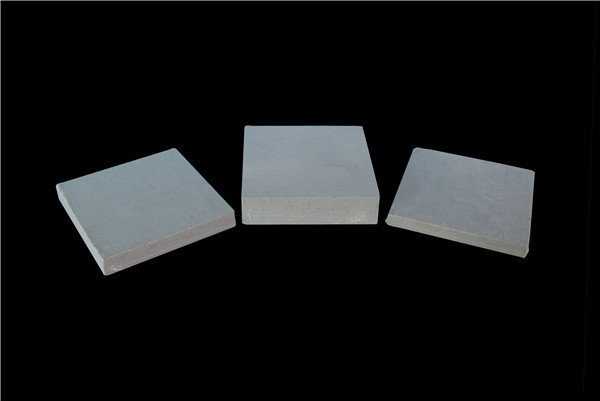

Product detail pictures:

Related Product Guide:

Sticking for the perception of "Creating goods of high quality and making good friends with people today from all around the world", we constantly set the interest of shoppers to begin with for Fast delivery High Temperature Ceramic Insulation - Microporous Insulation Board – MINYE , The product will supply to all over the world, such as: Canada, Czech republic, Hungary, Thus far, our item associated with printer dtg a4 may be shown in most foreign nations as well as urban centers, which are sought after simply by targeted traffic. We all highly imagine that now we have the full capacity to present you with contented merchandise. Desire to collect requests of your stuff and produce the long-term co-operation partnership. We very seriously promise:Csame top quality, better price; exact same selling price, higher quality.

High Quality, High Efficiency, Creative and Integrity, worth having long-term cooperation! Looking forward to the future cooperation!