China Cheap price Ceramic Fiber Manufacturers - Ceramic Fiber Paper / RCF Paper – MINYE

China Cheap price Ceramic Fiber Manufacturers - Ceramic Fiber Paper / RCF Paper – MINYE Detail:

Product Description

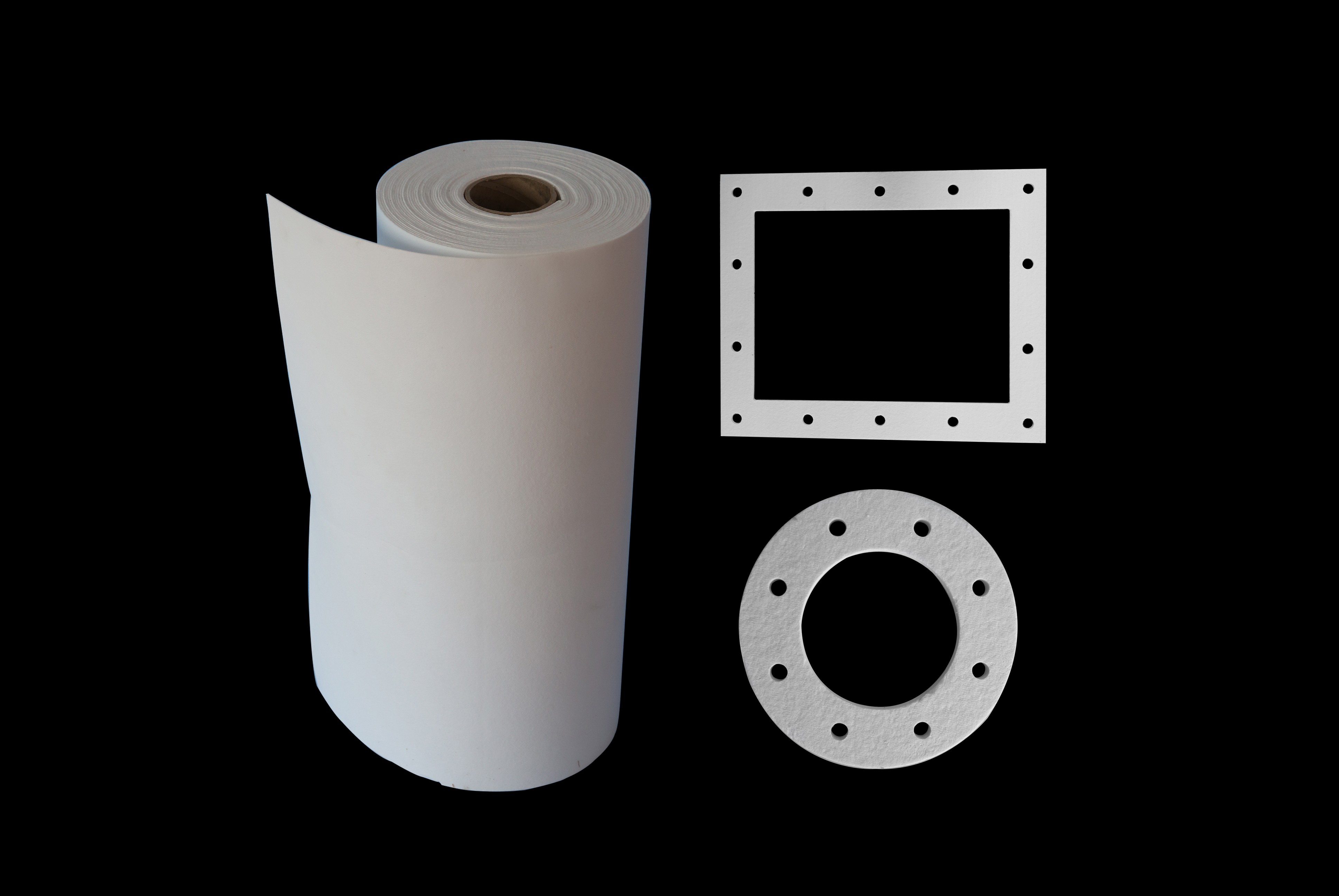

Ceramic fiber paper is manufactured with high purity ceramic fiber bulk fiber and small quantity binders, advanced processing technology make the fiber distribution very even. Ceramic fiber paper is used in high temp insulation, thickness and density is precisely controlled, binder get burned in using.

Typical Features

Excellent electrical insulation

Excellent mechanical processing

High tear resistance

High flexibility, precise thickness

Low shot content

Low heat capacity, low thermal conductivity

Typical Application

Industrial insulation, sealing, anticorrosion

Electrical heating device insulation

Instrument equipment insulation

Insulation for expansion joints

Industrial insulation materials

Molten metal gasket

Fireproof

Insulation in Auto

Typical product properties

| Ceramic Fiber Paper Typical Product Properties | |||

| Product Name | Standard Purity | High Al Purity | AZS |

| Product Code | MYTX-BZ-06 | MYTX-GL-06 | MYTX-HG-06 |

| Tensile Strength(Mpa) | ≥0.3 | ≥0.3 | ≥0.3 |

| Water Content(%) | P | ≤2 | ≤2 |

| Loss on ignition(%) | ≤10 | ≤8 | ≤8 |

| Nominal Density(kg/m³) | 190~220 | ||

| Width * Length Availability (mm) | 610mm or 1220mm width; length 80m, 40m, 30m, 20m,10m | ||

| Thickness Availability(mm) | 0.8, 1, 2, 3, 4, 5, 6, 10mm | ||

| Note: Test data shown are average results of tests conducted under standard procedures and are subject to variation. Results should not be used for specification purposes. The products listed comply to ASTM C892. | |||

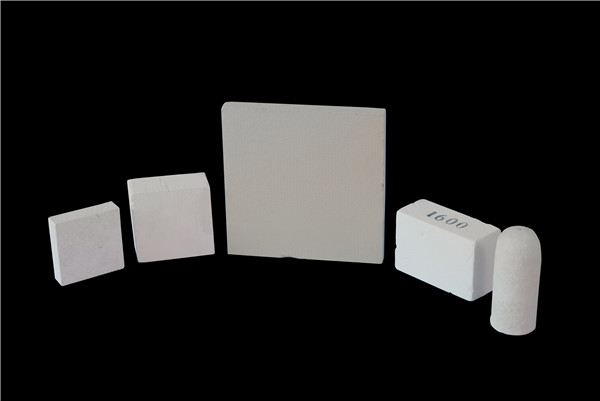

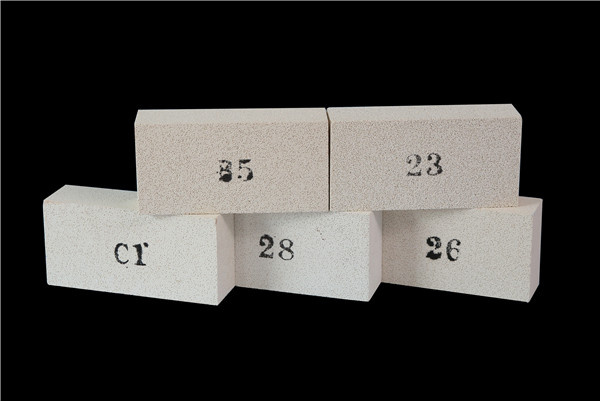

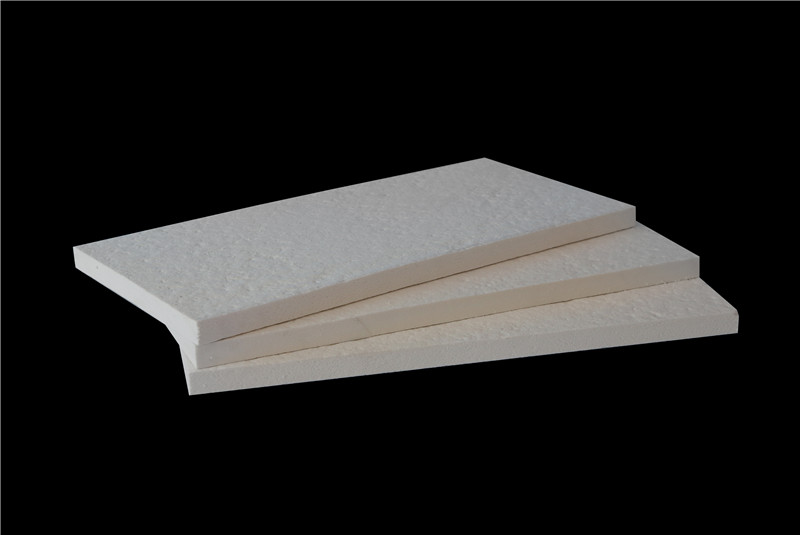

Product detail pictures:

Related Product Guide:

We are ready to share our knowledge of marketing worldwide and recommend you suitable products at most aggressive costs. So Profi Tools offer you finest benefit of money and we are ready to produce alongside one another with China Cheap price Ceramic Fiber Manufacturers - Ceramic Fiber Paper / RCF Paper – MINYE , The product will supply to all over the world, such as: South Korea, panama, Monaco, we are fully determined to control the whole supply chain so as to provide quality products at competitive price in a timely manner. We are keeping up with the advanced techniques, growing through creating more values for our clients and society.

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!

Write your message here and send it to us