Cheap PriceList for Refractory Ceramic Fiber - Ceramic Fiber Module / RCF Module – MINYE

Cheap PriceList for Refractory Ceramic Fiber - Ceramic Fiber Module / RCF Module – MINYE Detail:

Product Description

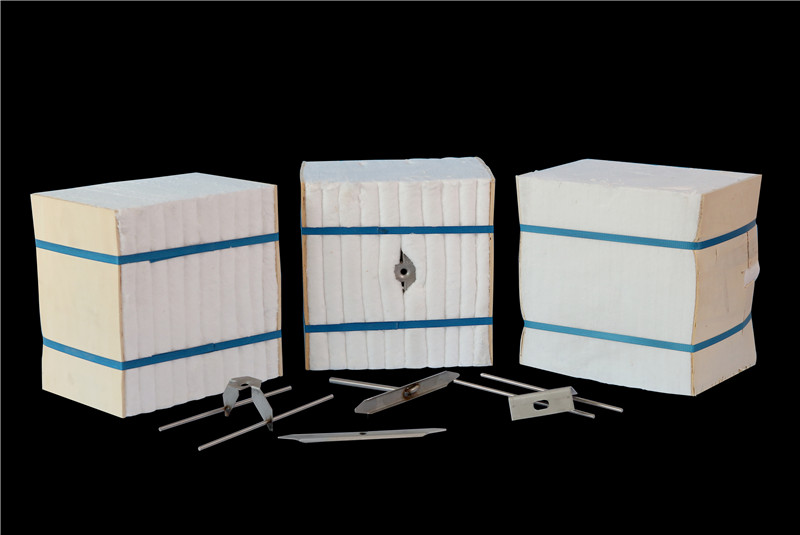

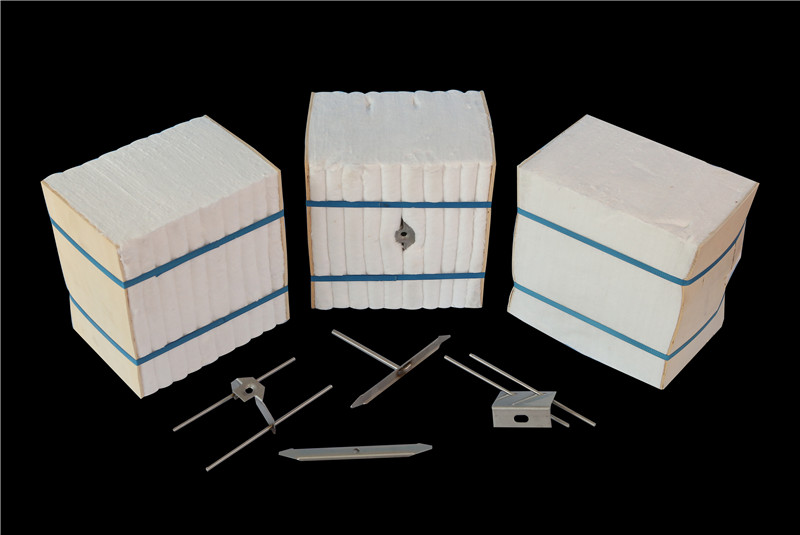

Ceramic fiber module is made from compressed ceramic fiber blanket. The module is designed to meet special thermal insulation requirements in industrial furnaces. During production, ceramic fiber module keep some compressive rate, to enable different direction expansion and no leaking after installation. Ceramic fiber module could match various anchoring systems to enable quick and efficient installation in most furnace linings.

Typical Features

Fast and easy installation

Fast and easy repair

Low thermal conductivity, good energy-saving effect

Low installation and repair costs

No need heating and maintaince, fast using after installation

Anchoring system away from hot face, working under low temp

Typical Application

Steel, Non-Ferrous

Machinery, Construction

Petrochemical and chemical industry

Typical product properties

| Ceramic Fiber Module Typical Product Properties | ||||||

| Module Product | Normal Kaolin | Standard Purity | High Purity | High Al Purity | Lower AZS | AZS |

| Temperature Grade℃ | 1050 | 1260 | 1260 | 1300 | 1300 | 1430 |

| Recommended Operating Tem℃ | ≤950 | ≤1100 | ≤1150 | ≤1200 | ≤1200 | ≤1250 |

| Product Code | MYTX-PT-09 | MYTX-BZ-09 | MYTX-GC-09 | MYTX-GL-09 | MYTX-DG-09 | MYTX-HG-09 |

| Permanent Linear Shrinkage(%) | 950℃×24h≤3 | 1000℃×24h≤3 | 1100℃×24h≤3 | 1200℃×24h≤3 | 1250℃×24h≤3 | 1350℃×24h≤3 |

| Nominal Density(kg/m³) | 180~240 | |||||

| Al2 O3 | ≥40 | ≥43 | ≥44 | ≥52 | ||

| Al2 O3 +SiO2 | ≥95 | ≥97 | ≥98.5 | ≥98.5 | ||

| Al2 O3 +SiO2 +ZrO2 | - | - | ≥99 | ≥99 | ||

| ZrO2 | - | - | 5~7 | ≥15 | ||

| Fe2 O3 | ≤1.0 | ≤1.0 | ≤1.0 | ≤1.0 | ≤0.5 | ≤0.5 |

| Availability(mm) | Per customers’s drawing | |||||

| Note: Test data shown are average results of tests conducted under standard procedures and are subject to variation. Results should not be used for specification purposes. The products listed comply to ASTM C892. | ||||||

Product detail pictures:

Related Product Guide:

We now have our individual sales group, layout team, technical team, QC crew and package group. Now we have strict high-quality control procedures for each procedure. Also, all of our workers are experienced in printing discipline for Cheap PriceList for Refractory Ceramic Fiber - Ceramic Fiber Module / RCF Module – MINYE , The product will supply to all over the world, such as: Johor, Liberia, Madras, With the best technological support, we have tailored our website for the best user experience and kept in mind your ease of shopping. we ensure that the best reaches you at your doorstep, in the shortest possible time and with the help of our efficient logistical partners i.e DHL and UPS. We promise quality, living by the motto of promising only what we can deliver.

Customer service staff and sales man are very patience and they all good at English, product's arrival is also very timely, a good supplier.